Ozone for the Postharvest Treatment of Fruit and Vegetables

Ozone for the Postharvest Treatment of Fruit and Vegetables

Recognized by the Ministry of Health as a “Natural aid for the sterilization of environments contaminated by bacteria, viruses, spores, molds and mites”, Ozone is a gas that is increasingly used in the food industry both in gaseous form and in the form of ozonated water (or Ozone water) due to the advantages associated with it. In particular, in the fruit and vegetable field, Ozone can be used successfully in the postharvest phase both during the fruit and vegetable washing phase and during the food storage phase in the cold room. Through its oxidizing and sanitizing action, Ozone is able to reduce the presence of ethylene thus lengthening the shelf life of stored products.

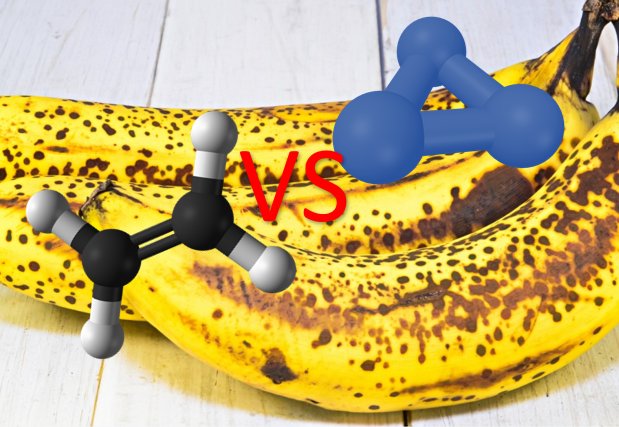

What is ethylene?

Ethylene is a hormone produced by many types of plants which affects the germination and aging of the plant itself: it causes fruit ripening, shoot development, leaf fall in autumn and the death of parts of the plant. Consequently, the reduction of ethylene results in a delay in maturation and therefore in an increase in the commercial life of the product.

In the book “Ozone in Food Industry” published by O’Donnell, Tiwari, Cullen, Rice (Wiley-Blackwell) it is possible to read the following statement:

Ozone is known to destroy ethylene gas, which is released when many fruits and vegetables begin to ripen. Basically, ethylene is converted into carbon dioxide, carbon monoxide and water after prolonged exposure to Ozone in a cold-damp storage environment (Bailey 1978).

What is the shelf life of a food product?

The term “shelf life” indicates the commercial life of the product, i.e. the time that passes between the production and consumption of the food without there being any risk to consumer health. In the case of fruit and vegetables, during this period these products inevitably undergo a progressive decline in quality and, if there is the appearance of rot, mold and the like, the product is compromised and cannot be consumed. Ozone, by reducing the presence of ethylene during storage and constantly sanitizing the product (thus reducing the presence of moulds, spores, fungi, etc.), helps significantly delay this natural deterioration.

Why Ozone?

Because, as anticipated, Ozone offers a series of indisputable qualitative, environmental and economic advantages.

- Among the qualitative advantages we find the extension of the commercial life of the product (food shelf life) as well as the reduction of ethylene, parasites, molds and fungi. Thanks to Ozone, a non-aggressive biological gas that leaves no residue, the use of chemical products which could instead alter the organoleptic characteristics of fruit and vegetables is avoided.

- Ozone and ozonated water do not require particular disposal and this represents a first advantage for the environment. Furthermore, since it does not need to be rinsed, Ozone consumes much less water than commonly used methods.

- As far as the economic advantages are concerned, using less water, as well as being good for the environment, translates into considerable economic savings. Finally, containing the presence of moulds, fungi and rot during the storage phase allows to considerably reduce product losses.

What are the applications of Ozone in the postharvest phase of fruit and vegetables?

- Product preservation and shelf life extension. The main application is the treatment of the product stored in cold rooms in order to contain the formation and spread of ethylene, moulds, fungi, bad smells and spores.

- Sanitize fruit and vegetables. Secondly, Ozone is used in the form of ozonated water (mixture of water with Ozone) for the sanitization of the product during the washing of vegetables and fruit and before storage in the cold room.

- Surface sanitization to reduce contamination. Finally, Ozone is used to sanitize surfaces, machinery and tools without the need for chemicals and without the need for rinsing.

How to wash fruit and vegetables at home?

What is applied on a large scale in the food industry can be replicated at home, benefiting from the same advantages. Ozone can in fact be used in the washing phase to sanitize fruit and vegetables without the aid of chemical agents such as sodium hypochlorite (commonly known as Amuchina) or products such as sodium bicarbonate which, despite claims to the contrary, it is unable to sanitize.

With a small domestic ozonizer like our PURITAS HOME, it is possible to sanitize fruit and vegetables quickly and effectively. In fact, it is sufficient to fill a basin with cold water, immerse the products to be sanitized, immerse the tube with the porous stone and finally activate the system for 5-10 minutes. At the end of the treatment, the products are perfectly sanitized.