Ethylene and Ozone

Why is it said that Ozone extends the shelf-life of stored foods?

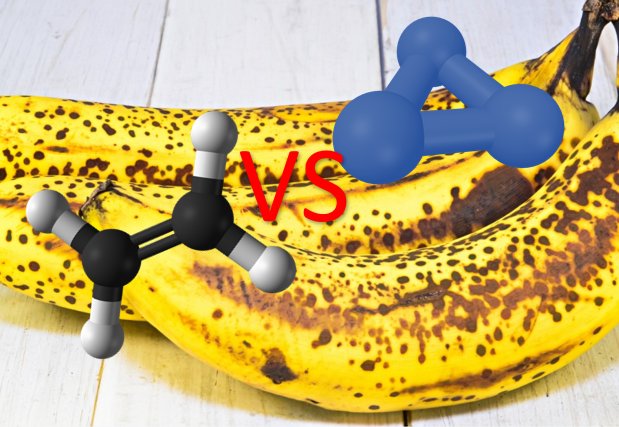

Ozone ability to reduce the presence of ethylene is among the main reasons why it is often stated that Ozone is able to increase the shelf-life of many food products such as fruit and vegetables in cold storage. But what exactly is ethylene and how is the action of Ozone able to reduce its presence?

ozone

What is ethylene?

Ethylene is a gas and phytohormone that can cause fruit ripening, shoot development, leaf fall in autumn, and the death of parts of the plant.

In climacteric fruits such as apples, bananas, apricots, kiwis, etc., ethylene production is high; in fact, these fruits continue to ripen even after harvesting. On the contrary, ethylene levels are lower in so-called non-climacteric fruits (e.g. blueberries, strawberries, cherries, citrus fruits, grapes, etc.). This is why it is recommended not to store fruit such as strawberries and raspberries near bananas or apples: the high ethylene production of these latter products is in fact capable of causing the fruit around them to ripen more quickly.

In climacteric fruits such as apples, bananas, apricots, kiwis, etc., ethylene production is high; in fact, these fruits continue to ripen even after harvesting. On the contrary, ethylene levels are lower in so-called non-climacteric fruits (e.g. blueberries, strawberries, cherries, citrus fruits, grapes, etc.). This is why it is recommended not to store fruit such as strawberries and raspberries near bananas or apples: the high ethylene production of these latter products is in fact capable of causing the fruit around them to ripen more quickly.

In some applications, ripening is even induced by ethylene. Fruit and vegetable products such as tomatoes are harvested before they are ripe and then ripen in a cold room by inserting precise quantities of ethylene gas inside.

However, when it is not required ethylene can cause serious damage by accelerating the deterioration of refrigerated products. In fact, a “cascade” effect can be generated where the ethylene released by ripe fruit also leads to the ripening of unripe products which then, in turn, will contribute to further increasing ethylene levels.

ozonizers

How does Ozone interact with ethylene?

Ozone can effectively counteract the rapid ripening of fruit and vegetables in cold storage by acting on this hormone. But how?

Well, even in this case the action of Ozone is oxidation: through a vigorous oxidizing action, ethylene is converted into carbon dioxide and water when the environment is humid and cold.

For instance, analyses on tomatoes have shown that the presence of residual Ozone was able to control and reduce the concentration of ethylene by up to 90% and the fruits also showed higher consistency values.

ozonator

How much Ozone is needed to break down ethylene?

The quantities of Ozone needed as well as the right concentrations to maintain within the cold room are determined following a careful analysis of the specific application and the variables involved (e.g. temperature, humidity, preserved products, storage methodology, etc.).

Introducing Ozone into the cold room without taking into account all the technical aspects listed above could even be counterproductive and lead to deterioration of the foodstuffs being stored. This is the reason why we always suggest relying on specialized companies such as Protea that deal exclusively with Ozone and boast twenty years of experience in the ozonation field, cold storage with Ozone and the use of Ozone in the food industry.

ozone cold rooms

What solutions does Protea offer for this application?

Over the years of experience in the field, Protea has developed a series of different solutions that adapt to the nature of the products stored (a cold room that stores dairy products must be treated differently from a cold room that stores oranges, for example), the type and volume of the cold room.

The range starts from products designed for blast chillers, refrigerated cabinets and small cold rooms such as the O3BC model up to the CUSTOM CELL or AMB O3 MAX lines which, depending on the configuration, can treat rooms up to 1,000 cubic metres in volume.

The range starts from products designed for blast chillers, refrigerated cabinets and small cold rooms such as the O3BC model up to the CUSTOM CELL or AMB O3 MAX lines which, depending on the configuration, can treat rooms up to 1,000 cubic metres in volume.

The entire range of Protea products for the treatment of foods stored in cold rooms is designed by Protea itself. This means that each model can be customized according to the Customer’s needs by means of modifications or additions of extra features (Ozone sensor, timers, remote monitoring, etc.).

ozonized water

To receive more information on our range of ozonizers for cold rooms, do not hesitate to contact our offices at 0584/361274 or by email at info@proteasrl.com.