Treatment of cold storage rooms with Ozone on board yachts

Treatment of cold storage rooms with Ozone on board yachts

Cold storage systems are indispensable on board every boat. In situations where you are at sea and it is not possible to return to the port for the supply of food products, cold storage rooms play a very important role: they should be, based on the characteristics of the boat, large enough to accommodate good quantities of food and able to store food for as long as possible. Protea integrates the normal cold storage carried out by the on-board cold rooms with the injection of Ozone, a gas capable of keeping the cell and the products stored inside sanitized, avoiding the cross-contamination of odors and fungal spores and helping to extend the shelf-life of products. The ozonating systems proposed by Protea can be applied starting from small boats (e.g. the cold rooms of fishing boats), up to mega yachts or cruise boats. This type of application is by no means new but has been used for many decades for the transport of exotic fruits on board cargo ships in order to maintain their quality throughout the journey.

What are the conventional solutions for the treatment of cold storage rooms on board yachts?

We can affirm that on board pleasure yachts there are no real standard installation systems for the sanitization of treatment of cold rooms. Below, we will list some methods commonly used in the industrial field but which hardly find application in the marine industry (especially on pleasure boats).

- UV-C lamps with germicidal power. UV lamps are well known for sanitizing in various fields. However, treatment with UV lamps is characterized by a number of obvious disadvantages. First of all, the UV-C lamps only act where the irradiation arrives: therefore, if it is an air treatment, only the illuminated air is sanitized; in the case of a surface treatment, only the irradiated surfaces are sanitized. Secondly, the efficiency of UV germicidal lamps decreases exponentially as soon as dirt is deposited on them: in a few weeks of operation it can also lead to a loss of effectiveness between 50% and 80%. Finally, the range of microorganisms on which the UV-C lamp has an effect is very small compared to Ozone.

- Controlled atmosphere. This technique consists in removing oxygen in the air and replacing it with mixtures of other gases that vary according to the products to be stored. Although the controlled atmosphere is a good method of cold storage (to prevent the formation of mold and bacteria and extend the shelf-life of products), it involves the use of complex machinery and procedures that do not easily adapt to ships, boats or pleasure craft. This is why controlled atmosphere cold rooms are an option that can only be pursued in the industrial sector.

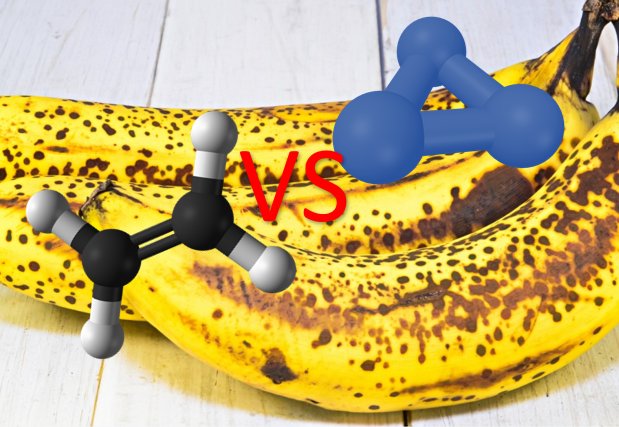

- Ethylene filters (or ethylene scrubber). There are filters to reduce the presence of ethylene produced from fruit and vegetables as ethylene is the hormone responsible for the maturation and deterioration of these products. In addition to the disadvantage of having to replace the filter frequently, it must be said that the ethylene scrubber focuses only on two types of product, namely fruit and vegetables (meat, fish and cheese do not produce ethylene). Furthermore, the ethylene filters do not guarantee any type of sanitization or removal of mold and bacteria on the surfaces of the cell or on the stored products.

What is the solution offered by Protea for the treatment of cold rooms on board yachts?

The solution offered by Protea ozonizers is the controlled and regular injection of Ozone into the cold room. The reason why Protea sees Ozone as the perfect solution for this application is not just one but there are many and relate to effectiveness, ease of installation and use, versatility and eco-compatibility. The Protea line of ozonizers dedicated to the sanitizing treatment of cold rooms is called CUSTOM CELL and each system is suitably sized on the basis of the volume of the cold room to be treated and the products stored. Furthermore, the CUSTOM CELL ozonating systems can be customized with a series of optional elements in accordance with the Customer’s requests: safety alarms, Ozone sensors, control panels, daily/weekly timers with remote programming, etc. The operation is roughly the following: once the cold room to be treated has been analyzed, the CUSTOM CELL ozonizer injects gaseous Ozone at regular intervals in order to maintain an adequate concentration to obtain sanitization results (odor, mold, bacteria, etc.) and allow operators to work easily in the cell (e.g. loading/unloading operations, goods handling, etc.).

What are the advantages of Protea ozonators compared to conventional solutions?

CUSTOM CELL, with its Ozone treatment, brings a series of advantages to simple cold storage in the cold room. The system can be sized and installed from small to large cold rooms such as fishing boats, mega yachts, giga yachts and cruise ships.

Here are the main advantages offered by Protea’s CUSTOM CELL ozonating systems.

- No recharges. Ozone is produced by CUSTOM CELL system only by means of electricity (low consumption). There is therefore no need to purchase refills and consumables as the treatment will be carried out automatically by generating the Ozone thanks to the air present in the environment.

- Free installation. The systems can be positioned about ten meters away from the ozone injection point, so as to allow their placement according to the spaces available on board. Not only new boats, therefore, but also already existing yachts, charter yachts and motor yachts in refit. A single CUSTOM CELL system can also handle several cold rooms, with consequent economic savings and technical simplifications for the Shipyard or the Customer.

- No particular maintenance. The CUSTOM CELL system does not need maintenance but only some simple periodic checks as a good rule for any electrical device.

- Sanitization of the cold room. There are no specific products capable of keeping the cold room and its products stored inside sanitized. Thanks to Ozone, a thorough sanitation of the whole room is guaranteed.

- Elimination of molds. Molds are among the main causes of deterioration of products stored in the cold room. Ozone is extremely effective in eliminating moulds and fungal spores and thus allows to stop rotting and safeguard healthy products.

- Elimination of ethylene. In the case of fruit and vegetables, Ozone through a chemical reaction is able to reduce the presence of ethylene (the hormone that causes fruit and vegetables to ripen). This Ozone effect helps to increase the shelf life of refrigerated products.

- Effective odor removal. The action of Ozone against odor molecules is powerful and immediate. No other product can actually remove odors like Ozone. Ozone, being a gas, is able to reach all points of the cold room, avoiding the onset of problems due to cross-contamination between different batches (e.g. meat and fish). For this reason, CUSTOM CELL systems can also be used for the elimination of odors inside the so-called garbage rooms.

- Extension of the shelf-life. The sanitizing action (elimination of molds, bacteria, fungi, etc.) together with the reduction of ethylene due to the use of Ozone allows to extend the life of food stored in the cold room (with different percentages based on the type of product).

- No residues. Following its action, Ozone quickly converts back into oxygen without releasing by-products or harmful chemical residues. The organoleptic qualities of the products stored in the cold storage room are not altered, on the contrary, the quality of the products is maintained in the best possible way for the entire storage period.

CUSTOM CELL ozonator line: sanitized cold storage room and products on board the yacht

CUSTOM CELL ozonator line: sanitized cold storage room and products on board the yacht

On the balance of pros and cons, the advantages of installing a CUSTOM CELL ozonator far outweigh the disadvantages. Thanks to CUSTOM CELL, in fact, it is possible to benefit from a series of qualitative improvements both for the cell and for the products stored in a simple and in no invasive way.

With a single system it is possible to sanitize the internal surfaces of the cold room, to sanitize the stored products without altering their characteristics, to reduce the presence of odors, to reduce the presence of ethylene… in other words, to improve and extend the conservation of food products stored in cold storage room.

Protea designs and manufactures the CUSTOM CELL system, adapting it perfectly to the cold storage room and the yacht under consideration; installation is therefore possible from small boats to larger motor yachts or mega yachts.

—

For more information on Protea ozonizers or Protea’s Ozone solutions for the Marine Industry or other applications, do not hesitate to contact our offices at 0584/361274 or by email at info@proteasrl.com.